O-rings

Product presentation

Apparently simple, it is instead a fundamental product for the functionality of much more complex sets.

The O-ring is a product with a wide range of uses, produced with materials that have been specifically studied and tested for the future applications. Used for coffee machines or for car injectors, for garden irrigation or large ship engines.

O-rings are everywhere.

Flexibility

Special processing

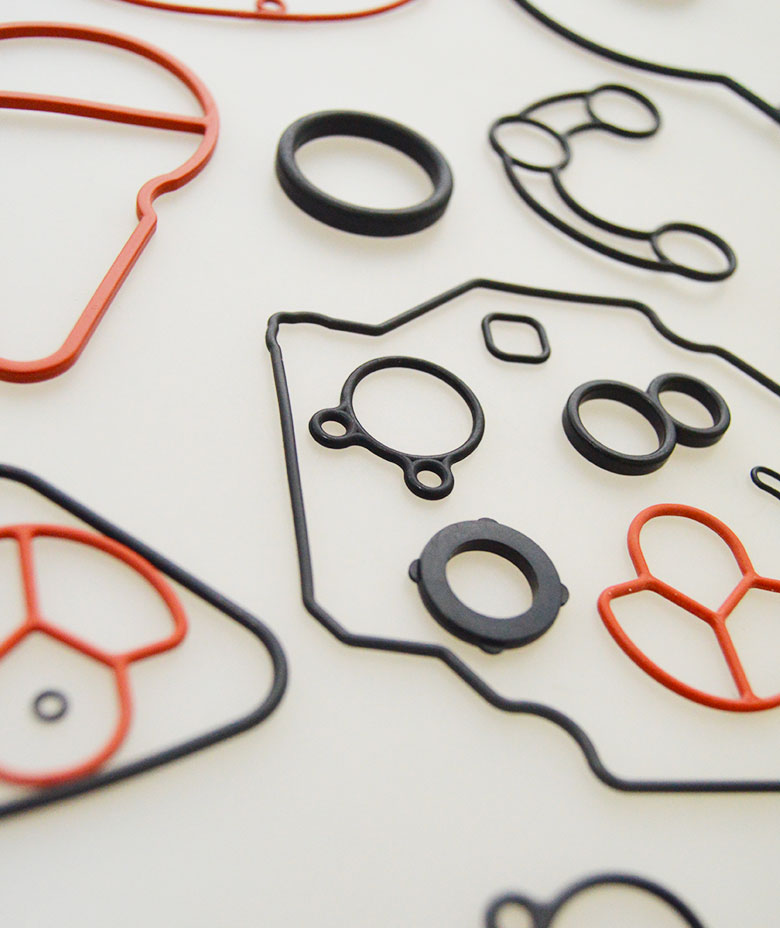

Even if Duci s.r.l. is specialized in the production of orings, we also study and produce special items according to specific drawings when compatible with our feasibilities. The possibility of studying and producing tools for our productions allows us to also create particular shapes for the production of frames, shaped rings, washers, membranes and other special products.

Belonging to the Sealcore group also allows us to continuously improve our skills and our technical knowledge and share our experiences in order to always have a complete view of the market.

Materials

Used compounds

To guarantee our presence in different markets and to study new applications, we have developed and tested more than 500 different compounds. Each material has been designed to ensure the best performance over time and offer the best quality and price.

The materials we use are:

NBR

EPDM

EPDM perossidici

FKM

CR

VMQ

HNBR

Each type of material can be produced with a minimum hardness of 30 shore at a maximum of 95 shore and with different colors if required. Our laboratory, with the help of specific instrumentation for chemical analysis on the compounds, is able to support you in the development of compounds for specific uses. Low temperatures, aggressive environments and harsh applications are just some of the problems solved by using the most suitable compounds.

Certified quality

Approvals

Our seals are successfully used in different market segments: starting from generic Industry, to automotive, drinking water, Healthcare, Hydraulic and Pneumatic, Oil & Gas, Semiconductors, Agricultural Industry as well as Renewable Energy. Our company has for years studied and certified materials also with the help of external and independent laboratories.This guarantees impartiality and the absolute certainty that the material complies with the necessary requirements.

Facilities

O-rings Production

O-rings Production: Thanks to materials and production systems evolution, today it’s possible to produce O-rings with high quality constant over time that, in some cases, allowed designers to replace more sophisticated sealing components with O-ring and to impose it as the more used static (sometimes dynamic) sealing element. From the simplest applications to the most severe conditions of use in complicated components, our O-rings offer guarantee of constancy in performances you are looking for.

O-rings Production: The increasing diffusion of applications using O-rings made it necessary an enlargement of sizes range. Today the market needs thousands of different combinations between diameters and cross-sections.

From the smallest O-ring with 1 mm internal diameter to the biggest one that, thanks to a new innovative production system, sets no limits to sizes. If we add the possibilty to choose among hundreds of different compounds with different hardnesses, colours and properties, the possibilities are really endless. Our continuous investment in technologies allowed us to realize a new production system to complete sizes range that has been produced until today from our company.O-rings Production. Almost endless internal diameter sizes, very low minimum order value, no tool charges unless special and very quick deliveries make this system an absolute innovation.